Chemical Name: 3-Ureidopropyltrimethoxysilane

Chemical Name

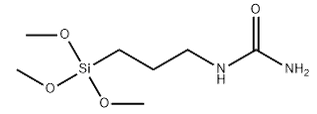

3-Ureidopropyltrimethoxysilane

Product Number

JH-A116

Structural Formula

Physical Indicators

CAS NO.: 23843-64-3

Density (20 ° C), g/cm3: 1.150

Boiling point: 220 ° C

Flash point: 99 ° C

Refractive index (nD25): 1.4610

Appearance: Colorless transparent liquid

Solubility: Soluble in most aliphatic and aromatic solvents such as alcohols and ethers. When hydrolyzed in water, the hydrolysate will self polymerize.

Purpose

1. Used as an additive or as a primer for coatings, inks, adhesives, and sealants such as phenolic, urea formaldehyde, furan, polyurethane, silicone, epoxy, phenolic, acrylic, etc., to improve the adhesion, corrosion resistance, weather resistance, water boiling resistance, and scrub resistance of resin coatings, extend service life, and improve the dispersibility and adhesion of pigments and fillers in the resin phase;

2. Used in resin grinding tools to improve the adhesion and water resistance between resin and abrasive, and to extend the service life of products;

3. This product can significantly improve the adhesive strength and sand strength of cold core box casting resin, reduce resin dosage and gas generation while maintaining sand strength, improve casting quality, and reduce scrap rate;

4. JH-A116 is suitable for inorganic materials such as glass, glass fiber, glass wool, mineral wool, mica, quartz and other siliceous materials, as well as metals and their oxides such as aluminum hydroxide, magnesium hydroxide, kaolin, talc powder, steel, zinc, aluminum, etc. However, it has little effect on fillers with no hydroxyl groups on the surface such as calcium carbonate, graphite, carbon black, and barium sulfate;

5. The polymers applicable to JH-A116 include (but are not limited to) phenolic, epoxy, furan, urea formaldehyde, melamine, polyurethane, acrylic acid, polyester, silicone, nitrile and other resins, as well as plastics such as nylon, PBT, PET, EVA, PP, PE, PVC, PVB, PVAC, PS, etc;

6. As a bonding promoter for alcohol based RTV silicone rubber, it can significantly improve its storage stability.

Packaging

5KG, 10KG, 25KG, 210L iron bucket, plastic bucket, or 1000L IBC bucket

Storage Conditions+

Sealed and stored in a cool, dry and ventilated place, moisture-proof and waterproof, away from sparks and heat sources

Sample Application

If you are interested in our products, please leave your contact information, and we will get back to you as soon as possible. Thank you!

Related Products

Copyright: Hubei Jianghan New Materials Co., Ltd.

This website already supports IPV4 / IPV6 bidirectional access

Website Construction: China Enterprise Power Yichang

Mobile Access

SAF Coolest v1.3 设置面板 TRGSX-ZEVE-QXSDE-AXD

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page